5052 aluminum plate is an AL-Mg alloy aluminum plate. Magnesium is the main alloying element. It is the most widely used anti-rust aluminum. It has high strength, especially fatigue resistance: high plasticity and good corrosion resistance, good weldability, poor machinability, and polishing.

Parameter

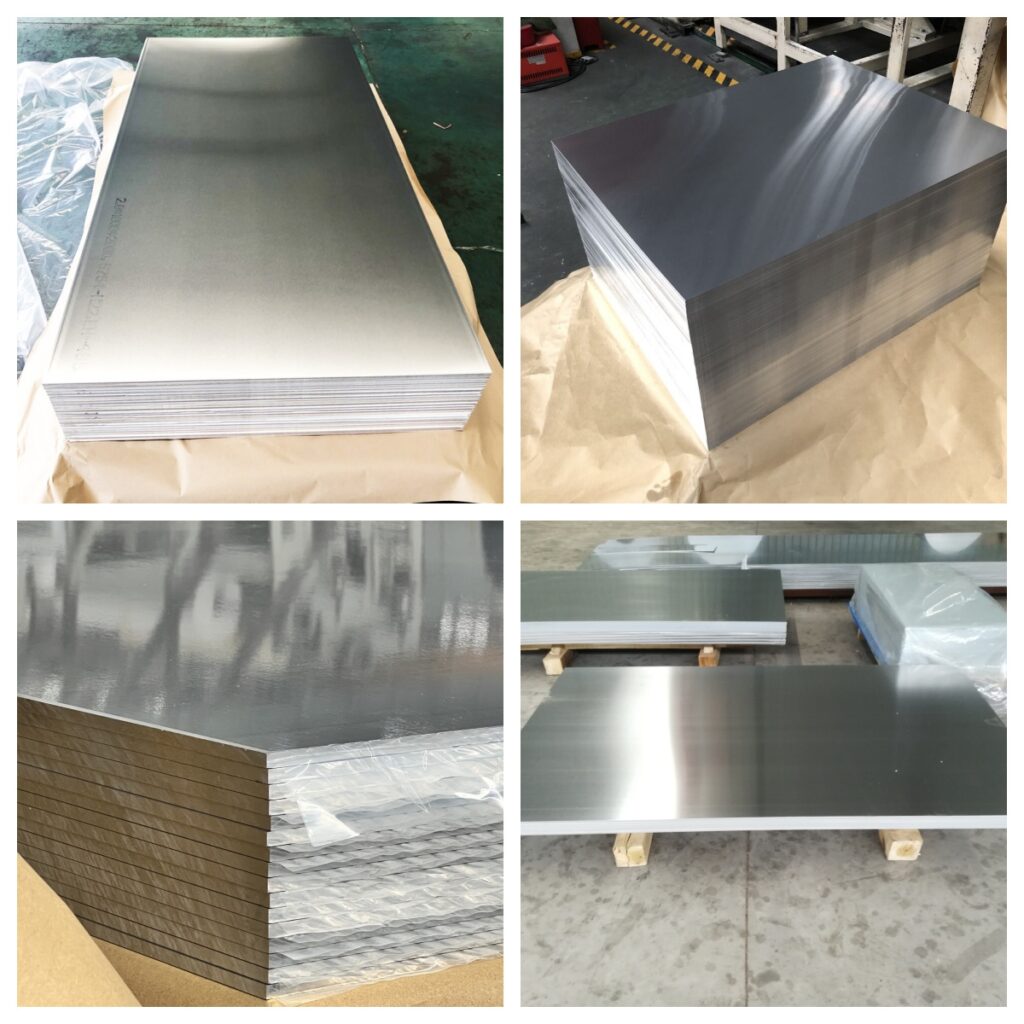

| Product name | 5052 aluminum plate |

| Temper | O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H116 |

| Thickness | 0.2-600 mm |

| Width | 20-2650 mm |

| Length | 500-16000 mm |

| Typical products | Alumina plates, silos, automotive aluminum plates, molds, etc. |

| MOQ | 3-5 tons |

Advantages of 5052 aluminum plate

- Lightweight: Aluminum’s hardness and low weight decrease ship weight, improving load resistance, speed, fuel efficiency, and range. A shallow draft enhances seaworthiness.

- Corrosion Resistance: Aluminum alloys surpass steel in corrosion resistance. It removes the need for extra measures like lead blocks and preserves seakeeping performance without weight increase.

- Easy Processing: Aluminum 5052 alloy is easily shaped with good toughness. Its non-magnetic nature avoids regular degaussing needed for steel ships, preventing electronic device interference.

Chemical composition

Aluminum Al: balance

Silicon Si: ≤0.25

Copper Cu: ≤0.10

Magnesium Mg: 2.2~2.8

Zinc Zn: ≤0.10

Manganese Mn: ≤0.10

Chromium Cr: 0.15~0.35

Iron Fe: ≤0.40

Note: Individual: ≤0.05; Total: ≤0.15

Mechanical properties

Tensile strength (σb): 170~305MPa

Conditional yield strength σ0.2 (MPa)≥90

Elastic modulus (E): 69.3~70.7Gpa

The annealing temperature is 345℃.

Process performance

- Forming performance

The alloy has good plasticity during hot processing. Forging and die forging temperatures are 420~475°C. Thermal deformation with a deformation rate of 80% is performed within this temperature range.

The cold stamping performance is related to the alloy state. The cold stamping performance in the annealed (O) state is good.

- Welding performance

The alloy has good performance in gas welding, arc welding, resistance welding, spot welding, and seam welding. The brazing performance is good, while the soft soldering performance is poor.

The weld has high strength and plasticity, and it reaches 90% to 95% of the strength of the base metal. 5A03 alloy can improve its air tightness and eliminate the tendency to crack.

- Machining performance

The alloy has better cutting performance in the cold work-hardened state.

Applications of 5052 aluminum plate

- Automotive aluminum alloys

- High-end curtain wall panels

- 3C products, computer brackets

- High-end oxidized materials

- Aluminum furniture

- Door panels/door handles

- Cans/lids

- Blinds

- Decorations

- Trolley cases

- Signs

Aluminum alloy thick plate use

Silos, flange materials, GIS shells, yachts, underwear molds/shoe molds, gas cylinders, precision processing, etc.

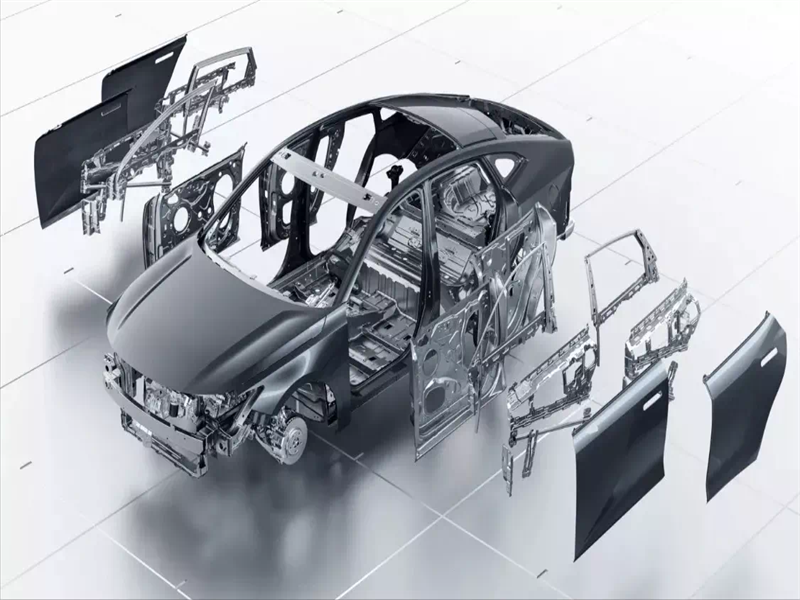

5052-h32 Aluminum plate for automobiles

Car engine outer panels, passenger car trunk panels, passenger car anti-skid decorative panels, automobile fuel tanks, etc.

New energy buses are produced using aluminum alloy materials, and the bus hatch is made of 5052 aluminum plate material.

5052 aluminum plate is used for bus hatches. These materials reduce the weight of the bus’s load-bearing structure, thus improving its comfort. Due to the reduced weight and corrosion resistance of aluminum alloys, this greatly reduces vehicle use and maintenance costs.

Advantage: 5052 aluminum plate products have stable performance, good formability, and corrosion resistance.

Applications: Trolley cases, fuel tank materials, LCD back panels, fuel tank materials, door panels, high-voltage switch housings, etc.

What is the market processing fee for 5052 aluminum plates for bus hatches?

The price of 5052 aluminum plate has a certain correlation with the specific alloy state, alloy thickness, and width. Traditional boards are cheaper. Some users will use extra-wide boards, which are slightly more expensive. Secondly, it is also related to external factors such as market conditions, supply and demand relations, and sales models.

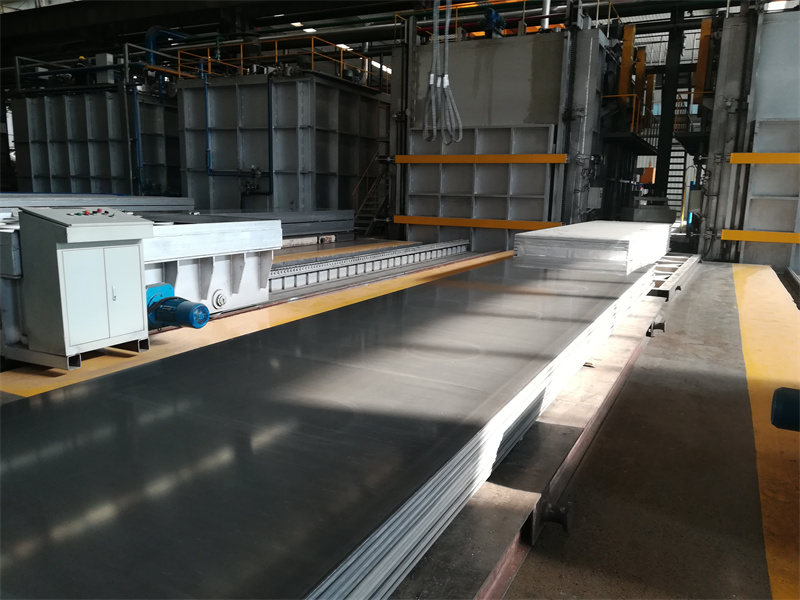

Henan Gusto Trading Company produces 5052 aluminum plates with thicknesses of 1-500mm. For special specifications please call us. We can customize products of different specifications on demand and accept large orders.

[wpforms id=”27″]