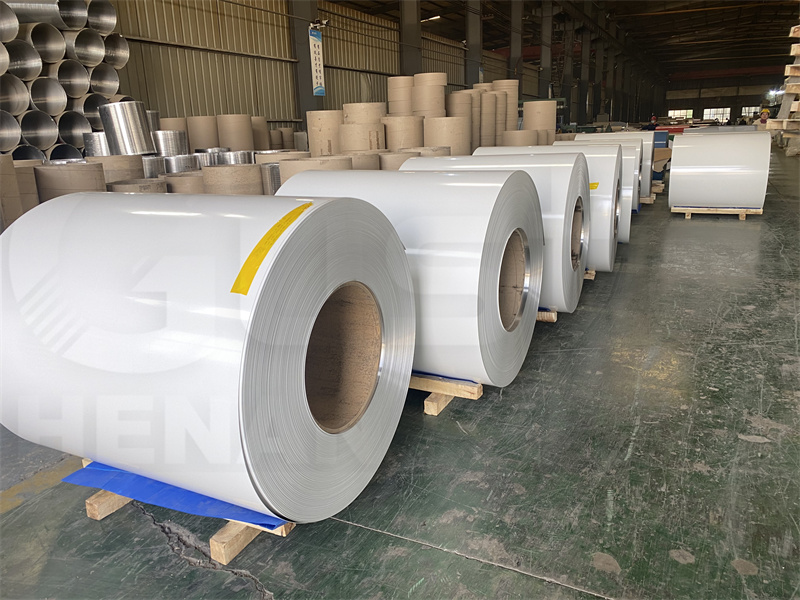

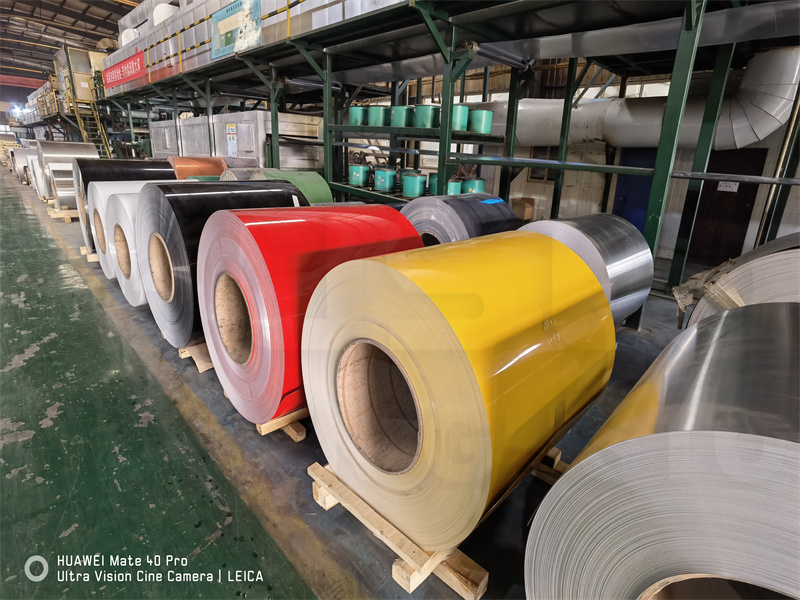

Coated aluminum is painted on the surface of aluminum substrates. Common ones include PE color-coated aluminum coils and PVDF color-coated aluminum coils. Its performance is very stable and has good corrosion resistance. It is a new type of material. It has wide use in ACP, flooring and walls, aluminum louvers, composite panels, aluminum ceilings, cans, and electronic products.

Parameter

| Product name | Coated aluminum |

| Alloy | 1050/1060/1100/3003/3004/5052/5105 |

| Temper | H24/H26 or as per customer’s requests |

| Coating thickness | As per customer’s requests |

| Thickness (mm) | 0.25-5 |

| Width (mm) | Under 1350 (as per customer’s requests) |

| Capacity /month | 500 tons |

| MOQ | 2-4 tons |

The Difference of PE and PVDF

They have some differences in the following ways.

- Indoors, PE offers a 10-year guarantee, while PVDF, suitable for outdoor use, provides a 15-20 year warranty.

- PE is only single and double-coated, PVDF includes double-coated and three-coated, and more.

- PE is cheap, and PVDF is expensive. The technology it uses is more high-end.

- PE is mostly used for the coil. The thickness of the coil line: is 0.2-1.35 mm, maximum width is 1350 mm. PVDF is mostly used for the plate. The thickness of the plate line: is 1.5-5.0 mm, maximum width is 1750 mm.

- PE gloss is high and can reach more than 90%.

In addition to the above differences, they also have things in common.

- They can do solid and metallic.

- They both have a double coating.

Feature of coated aluminum

- Smoothness: There are no composite high-temperature indentations on the surface. There is no residual stress on the board surface and no deformation after shearing.

- Decorative: Painted with wood grain and stone grain, it has a realistic physical texture and a vivid natural beauty. The patterns can make randomly, giving customers a wide range of personal choices, and giving people more beautiful enjoyment.

- Weather resistance: The paint of continuous coating and high-temperature baking has high gloss retention, good color stability, and minimal color difference. PE paint has a 10-year warranty, and PVDF paint has a 20-year or more warranty.

- Mechanical: Use high-quality aluminum materials, plastics, and adhesives, and adopt advanced composite technology. The product has the bending and flexural strength required for decorative panels. Under four-season climate conditions, changes in wind pressure, temperature, humidity, and other factors will not cause bending, deformation, expansion.

- Environmental protection: It is resistant to salt, alkali, acid rain and corrosion and will not corrode or produce poisonous bacteria. It does not release any toxic gases does not cause corrosion of keels and fixings, and is flame retardant. According to national regulations, it shall not be lower than the B1 level.

Applications of coated aluminum

Coated aluminum has a rich color range, whether they are residential buildings, large commercial outlets, or conventions and exhibitions.

Good plasticity and machining properties make it an ideal material for various architectural shapes.

It can always meet the different requirements of modern and classical architectural styles, making the building colorful.

The following are its common applications:

- Building and Construction: in the building and construction industry exterior cladding, roofing, and facades. Its vibrant colors, corrosion resistance, and low maintenance make it a popular choice for commercial buildings and residential homes. Such as aluminum-plastic panels, aluminum honeycomb, roof corrugated panels, fireproof veneer panels, aluminum ceilings, rolling shutter doors, and gutters.

- Transportation: in the transportation sector for manufacturing vehicle bodies, trailers, and panels. Its lightweight, high strength, and corrosion resistance make it suitable for enhancing the durability of automobiles and trucks.

- Household Appliances: in the production of household appliances such as refrigerators, ovens, and washing machines. Its corrosion resistance, ease of cleaning, and high-temperature resistance increase service life.

- Furniture and Interior Design: in furniture manufacturing and interior design for creating modern and stylish pieces. It is suitable for furniture frames, cabinets, and decorative panels due to its wide range of color options.

- Electronic appliances: computer cases, electrical panels, lighting, solar reflectors.

If you are interested in our products, please contact us.

[wpforms id=”27″]