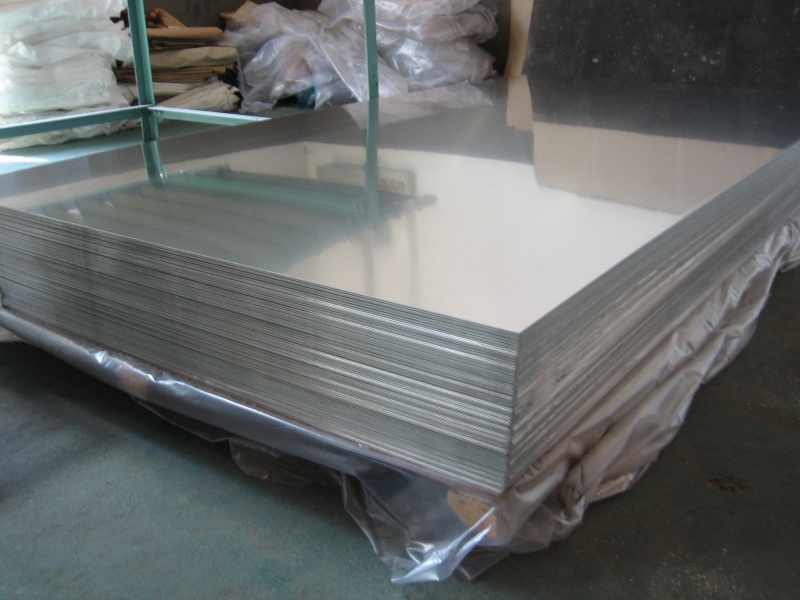

3003 aluminum sheet is a versatile material renowned for its excellent formability, corrosion resistance, and weldability. Belonging to the 3xxx series of aluminum alloys, it sees common use in various industries. Its exceptional performance and reliability contribute to its popularity.

Introduction

3003 aluminum sheet has high strength, good formability, weldability, and corrosion resistance. It is used for processing parts and components that require good formability, high corrosion resistance, and good weldability. Such as kitchen utensils, food, and chemical product processing and storage devices, various pressure vessels and pipes processed by thin plates, general utensils, heat sinks, cosmetic boards, photocopier rollers, and ship materials.

Parameter of 3003 Aluminum Sheet

| Product name | 3003 aluminum sheet |

| Temper | O, H12, H14, H16, H18 |

| Thickness | 0.2-500 mm |

| Width | 100-2600 mm |

| Length | 500-16000 mm |

| Color | RAL colors, customized colors |

| Protection | PE protective film |

| MOQ | 3-5 tons |

| Typical use | Antenna pot materials, shutter materials, heat sinks, aluminum substrates for color coating, roof tiles, road signs, battery casings, signs, car body skins, etc. |

Physical properties

Chemical composition

- Aluminum Al: balance

- Silicon Si: 0.6

- Copper Cu: 0.05–0.2

- Zinc Zn: 0.10

- Manganese Mn: 1.0–1.5

- Iron Fe: 0.7

- Single: 0.05

Mechanical properties

Tensile strength σb (MPa): 120-160

Conditional yield strength σ0.2 (MPa) ≥85

Specimen size: all wall thicknesses

Note: Longitudinal mechanical properties of pipe at room temperature

The national standard for aluminum plates and strips (GB/T 3880-2006) is a unified standard for aluminum alloy plates and strips.

Heat treatment process

- Complete annealing: heating to 390~430℃; depending on the effective thickness of the material, the holding time is 30~120min; cooling in the furnace to 300℃ at a speed of 30~50℃/h, and then air cooling.

- Rapid annealing: Heating at 350~370℃; depending on the effective thickness of the material, the holding time is 30~120min; air or water cooling.

- Quenching and aging: quenching at 500~510℃, air cooling; artificial aging at 95~105℃, 3h, air cooling; natural aging at room temperature for 120h

Advantages of 3003 Aluminum Sheet

- Formability: 3003 Aluminium Sheet exhibits outstanding formability, allowing it to be easily shaped, bent, and formed into desired configurations without cracking or tearing.

- Corrosion Resistance: With a protective oxide layer, 3003 Aluminium Sheet offers excellent resistance to corrosion, making it suitable for use in marine, chemical, and other corrosive environments.

- Weldability: 3003 Aluminium Sheet is highly weldable using various methods such as MIG, TIG, and spot welding, enabling efficient fabrication and assembly processes.

- Lightweight: As an aluminium alloy, 3003 Aluminium Sheet is lightweight yet durable, making it ideal for applications where weight reduction is essential without compromising strength and performance.

- Highly Recyclable: Being environmentally friendly, 3003 Aluminium Sheet is highly recyclable, contributing to sustainable manufacturing practices and reducing environmental impact.

Applications of 3003 Aluminum Sheet

- Construction: 3003 Aluminium Sheet widely use in the construction industry for roofing, siding, and architectural applications due to its corrosion resistance and formability.

- Transportation: The transportation sector utilizes 3003 Aluminium Sheet for manufacturing vehicle body panels, trailers, and other components. These require lightweight and corrosion-resistant materials.

- Packaging: The packaging industry employs 3003 Aluminium Sheet for manufacturing containers, cans, and packaging foils. This is due to its formability and weldability, ideal for food and beverage products.

- HVAC/R: In HVAC/R systems, 3003 Aluminium Sheet manufactures heat exchangers, evaporator coils, and condenser fins. This is due to its thermal conductivity and corrosion resistance.

- Electronics: The electronics industry utilizes 3003 Aluminium Sheet for manufacturing electronic enclosures, chassis, and components. This is because of its lightweight, electrical conductivity, and corrosion resistance properties.

Overall, 3003 Aluminum Sheet is preferred by manufacturers across various industries. It offers a wide range of advantages and applications, being high-quality, reliable, and versatile.

If you need 3003 aluminum sheet, please contact us.

[wpforms id=”27″]