Anodized aluminum coil is a continuous strip of aluminum that has undergone an electrochemical process to create a durable, corrosion-resistant oxide layer.

Premium Surface Finish for Architectural & Industrial Applications

Specifications of Anodized Aluminum Coil

| Item | Details |

|---|---|

| Product Name | Anodized Aluminum Coil |

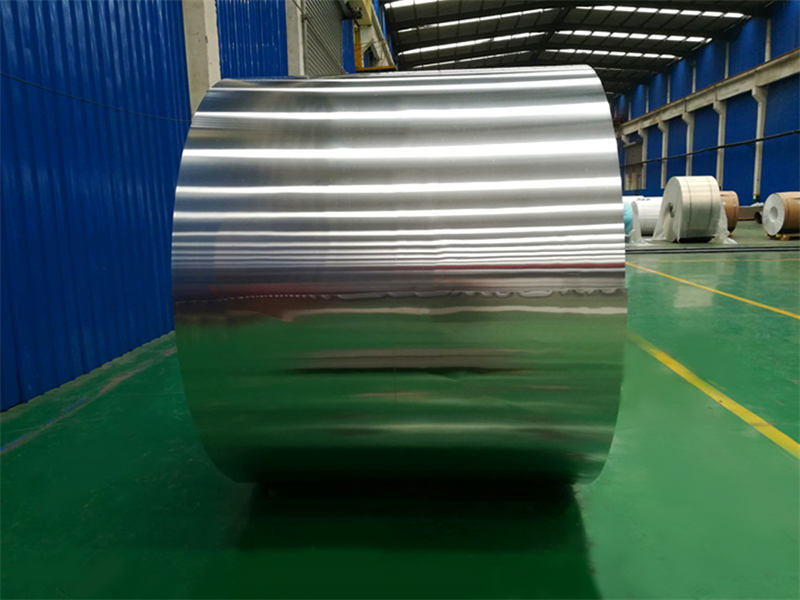

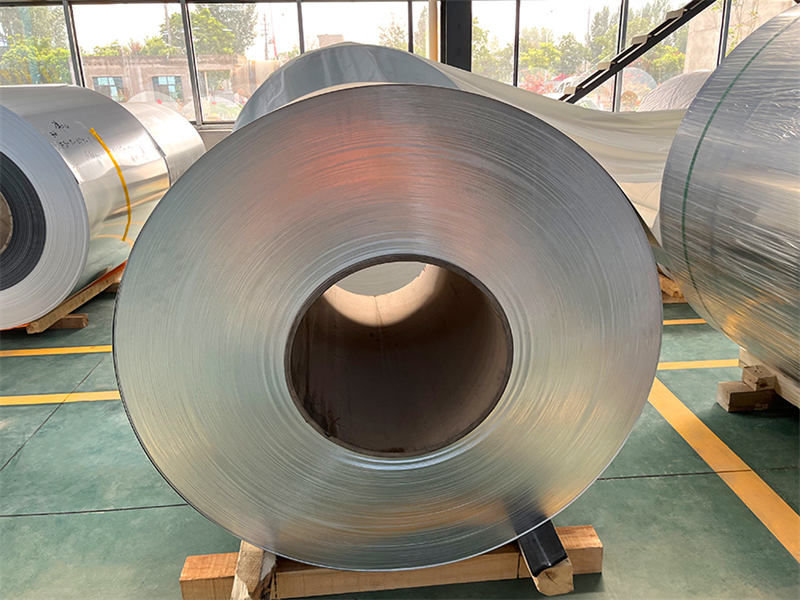

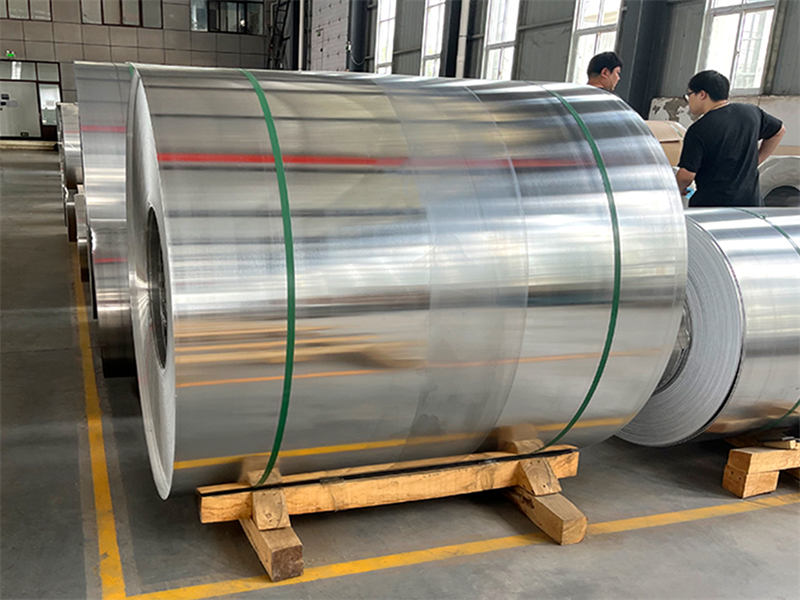

| Classification | Coil / Roll |

| Thickness | 0.2mm – 3.0mm |

| Width | 20mm – 1600mm |

| Alloy | 1050, 1060, 1100, 3003, 5052, 5005 |

| Temper | H14, H24, H26, O |

| Surface Finish | Bright, Matte, Brushed, Colored |

| Color Options | Silver, Black, Bronze, Gold, Champagne |

| Coating | Anodic oxide film (thickness 5-25μm) |

| Packaging | Eye to Sky or Eye to Wall, Wooden Pallet |

What Is Anodized Aluminum Coil?

Anodized aluminum coil is aluminum that has gone through an electrochemical process to form a corrosion-resistant, durable, and decorative oxide layer on the surface. This layer enhances aluminum’s natural properties, making it ideal for both interior and exterior uses.

Anodizing also improves:

- Surface hardness

- UV resistance

- Color durability

- Adhesion for printing or gluing

Classification of Anodized Aluminum Coils

| Type | Process | Thickness Range | Surface Finish |

|---|---|---|---|

| Type I | Chromic Acid Anodizing | 0.2-6.0mm | Matte appearance |

| Type II | Sulfuric Acid Anodizing | 0.3-8.0mm | Clear/Colored |

| Type III | Hardcoat Anodizing | 1.0-10.0mm | Extra-thick layer |

Standard Thickness Options

| Thickness (mm) | Common Uses |

|---|---|

| 0.2-0.5 | Electronics, lighting fixtures |

| 0.5-1.2 | Architectural cladding, signage |

| 1.2-3.0 | Automotive parts, marine applications |

| 3.0+ | Industrial equipment, aerospace components |

Alloy Selection Guide

| Alloy Series | Best For | Anodizing Performance |

|---|---|---|

| 1000 (1050, 1100) | Decorative applications | Excellent color uniformity |

| 3000 (3003, 3004) | Building facades | Good formability |

| 5000 (5052, 5083) | Marine environments | Superior corrosion resistance |

| 6000 (6061, 6063) | Structural components | Best for hardcoat anodizing |

Packaging Standards

To protect the anodized surface during transit:

- Inner Wrapping:

- PE protective film

- VCI (Vapor Corrosion Inhibitor) paper

- Outer Packaging:

- Waterproof craft paper

- Steel or wooden crates for export

- Edge protectors on all corners

- Coil Specifications:

- ID: 150mm/300mm/500mm

- OD: Max 1800mm

- Weight: 2-10 tons per coil

Key Benefits of Anodized Aluminum Coil

- Durability: 3-5x more scratch-resistant than paint

- Maintenance: Only requires occasional cleaning with mild detergent

- Color Options: Available in 20+ standard colors (RAL codes)

- Eco-Friendly: No VOCs or hazardous chemicals

Manufacturing Process

- Coil Cleaning: Alkaline bath removes oils and impurities

- Etching: Creates uniform surface texture

- Anodizing: Electrochemical oxide layer formation

- Coloring (optional):

- Electrolytic coloring (bronze/graphite tones)

- Dip coloring (full spectrum colors)

- Sealing: Hot water or chemical sealant closes pores

Advantages of Anodized Aluminum Coil

- ✅ Corrosion resistance (suitable for marine and industrial environments)

- ✅ Long-lasting surface finish without peeling or flaking

- ✅ Easy maintenance and cleaning

- ✅ Environmentally friendly (non-toxic, recyclable)

- ✅ Lightweight compared to other coated materials

Common Applications of Anodized Aluminum Coil

| Industry | Use Case |

|---|---|

| Architecture | Facades, ceilings, wall panels, decorative cladding |

| Electronics | Mobile phone casing, computer panels |

| Furniture | Kitchen cabinets, drawer fronts, shelves |

| Transportation | Bus, train interiors, automotive trim |

| Signage | Signboards, display frames, logos |

| Lighting | LED housings, reflective surfaces |

| Solar Panels | Frames and covers |

| Consumer Goods | Appliance covers, picture frames |

Popular Alloys for Anodized Aluminum Coil

1050 / 1060 / 1100 (Pure Aluminum Series)

- High ductility and corrosion resistance

- Ideal for general indoor decorative use

- Soft and easy to process

3003 Alloy (Al-Mn Series)

- Better strength than 1000 series

- Excellent corrosion resistance

- Suitable for roofing, siding, and kitchen cabinets

5005 / 5052 Alloy (Al-Mg Series)

- Excellent formability and durability

- High corrosion resistance, especially in saltwater environments

- Perfect for outdoor architecture and marine applications

Packaging & Delivery

We ensure safe packaging to prevent coil damage during transport:

- 🧊 Plastic film + Kraft paper wrapping

- 📦 Steel or wooden pallet secured with edge protectors

- 🚚 Eye to wall or eye to sky packing for easy loading

- 📦 Customized packaging is also available upon request

Why Choose Our Anodized Aluminum Coil?

- ✅ In-house anodizing production with strict quality control

- ✅ Custom thickness, color, and finish available

- ✅ Fast lead time and global export experience

- ✅ Factory-direct pricing from Worthwill Aluminum

Frequently Asked Questions (FAQ)

Q: What thickness is best for architectural anodized coil?

A: 0.8mm to 2.0mm is commonly used for facades and ceilings.

Q: Can you match custom colors?

A: Yes, we offer color customization based on RAL or Pantone codes.

Q: Is the anodizing layer scratch-proof?

A: It’s not 100% scratch-proof, but significantly more durable than paint.

Contact Us for Your Anodized Aluminum Coil Needs

Looking for high-quality anodized aluminum coils?

📧 Email: sales@wwaluminum.com

📞 WhatsApp: +86 15736973771

We supply customized sizes, alloys, and finishes tailored to your project!