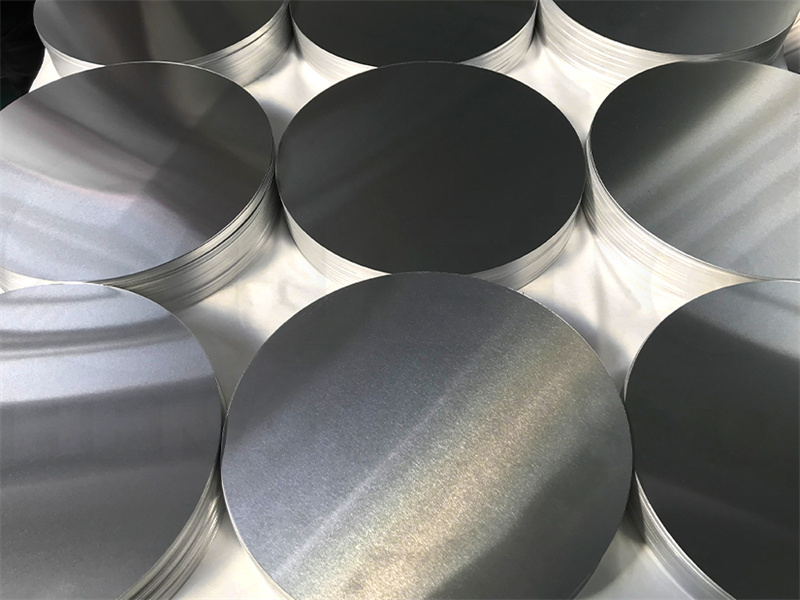

Aluminum circle is one of the most widely used deep-processing products of aluminum alloy plates and strips. Aluminum circles offer durability, versatility, and superior performance features. So it provides a wide range of applications in various industries. It widely use in electronics, daily chemicals, electrical appliances, insulation, machinery manufacturing, military industry, molds, construction, and other industries. Such as kitchenware supplies such as non-stick pans, and pressure cookers. And hardware supplies such as lampshades, water heater shells, stretch tanks, etc.

Introduction to Aluminum Circle

Aluminum circle, also known as aluminum disc or aluminum round blank. It is precisely cut circular pieces of aluminum sheet or coil. These circles are usually made by processes such as stamping or spinning. Available in a variety of diameters, thicknesses, and alloys to suit different applications.

Parameter

| Product name | Aluminum circle |

| Alloy | 1050/1060/1100/3003/5052 |

| Temper | O, H12, H14, H32 |

| Thickness (mm) | 0.2-10 |

| Diameter (mm) | 50-1550 |

| MOQ | 2-4 tons |

| Delivery | 22-30 days |

| Package | Standard seaworthy exporting packing |

Remark: Special specifications need to be customized according to requirements. We have various moulds every 5 mm.

Advantages

- Formability: Aluminum discs have excellent formability. It can be easily shaped, bent, and formed into the desired shape. This property makes them suitable for applications requiring complex shapes or precise dimensions.

- Lightweight: The aluminum ring is durable and lightweight. This is easy to handle, transport, and install. This feature reduces overall project weight and shipping costs while maintaining structural integrity.

- Corrosion resistance: Aluminum itself has corrosion resistance. Aluminum discs are therefore ideal for indoor and outdoor applications. They can withstand moisture, humidity, and harsh environmental conditions without rusting or deteriorating.

- Thermal conductivity: The aluminum ring has excellent thermal conductivity, which is conducive to efficient heat transfer. This property makes them suitable for applications requiring heat dissipation or cooking surfaces, such as cookware, radiators, and appliances.

- Corrosion resistance: Aluminum has natural corrosion resistance, making aluminum circles suitable for outdoor and marine applications. They can withstand moisture, humidity, and harsh weather conditions without rusting or deteriorating, ensuring long-term durability.

- Versatility: Aluminum discs are incredibly versatile and can find applications in a variety of industries. Their adaptability makes them indispensable in a variety of applications, from cookware and kitchen appliances to automotive parts, signage, and lighting fixtures.

Applications of Aluminum Circle

- Cooking kitchen: Aluminum discs commonly use as substrates for kitchenware and tableware. Such as pots, frying pans, woks, and pizza pans, due to their excellent thermal conductivity and corrosion resistance.

- Auto Parts: In the automotive industry, aluminum discs can use to make fuel tanks, radiators, wheel spokes, and decorative trim.

- Signage and Display: Such as custom shapes, sizes, and finishes. They also use for signage boards, nameplates, labels, and decorative elements.

- Electronics and appliances: Such as capacitor casings, speaker cones, and radiators, due to their excellent thermal conductivity and formability.

- Industrial Applications: Such as pressure vessels, chemical storage tanks, mechanical parts, and decorative architectural elements for their durability and corrosion resistance.

About our factory

First of all, we are a manufacturer specializing in the production of aluminum discs.

Our company has 8 internationally advanced production lines, each with an annual output of 150,000 tons. It is a fully automatic and integrated aluminum disc production equipment. That can punch and blank the discs directly on the aluminum coil without the need for other processes. This equipment automatically selects the most suitable layout method according to the width and the diameter. It directly performs blanking processing and production. It is far superior to other wafer blanking methods and increases production speed. All production is by national standards and relevant industry standards.

Our company has carried out extensive exchanges and friendly cooperation around the world, which has effectively supported the healthy and rapid development of the industry.

If you need the aluminum circle, you can contact us.

[wpforms id=”27″]