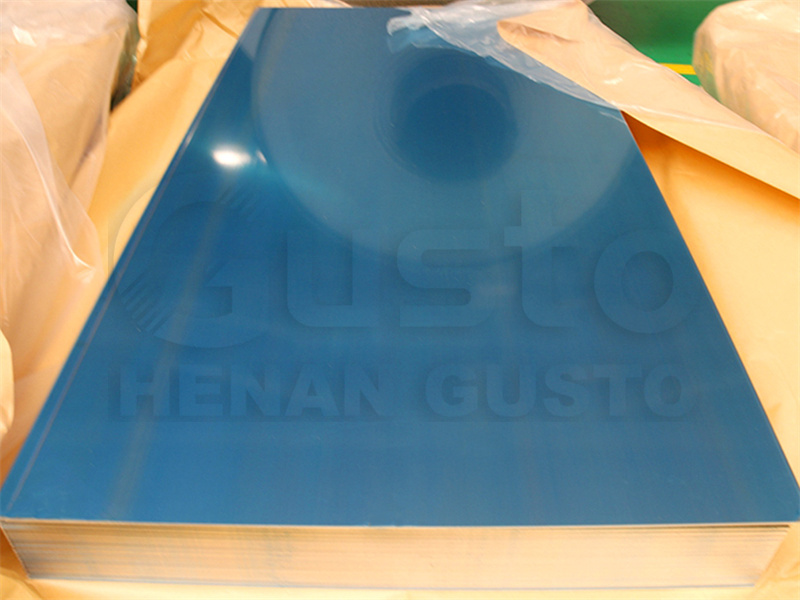

1100 aluminum sheet is industrial pure aluminum, aluminum content (mass fraction) is 99.00%, can not be strengthened by heat treatment. 1100 is usually used to require good form-ability and high corrosion resistance, such as food and chemical handling and storage equipment, sheet metal products, hollow hardware processed with drawn cargo spinning, welding key combinations, reflectors, nameplates, etc.

Specification

| Product name | 1100 Aluminum plate |

| Alloy | 1050/1060/1070/1100/3003/3004/3105/5052/5056/5083/5754/6061 |

| Temper | O,H12,H14,H16 H18,H19,H22,H24 H26,H28,H32,H34 H36,H38 |

| Width | 100mm-2650mm |

| Length | 500mm-16000mm or customized |

| Standard | ASTM |

| Certificates | ISO, SGS |

| MOQ | 1 TON |

| Delivery time | customize: 15-20 days, Ready stock: 5-7days |

| Packaging | Seaworthy Wooden pallet ,Wooden case,Aluminum plate case |

| Payment Terms | T/T,L/C,D/P. |

Re: Special sizes can be customized.

Feature About 1100 aluminum sheet

- High elongation

- Tensile strength

- Excellent electrical conductivity

- Goodform-ability

- High corrosion resistance

- Do not need high strength parts

- High thermal conductivity

- Good weld-ability

- Low Strength

- Low Density

Application

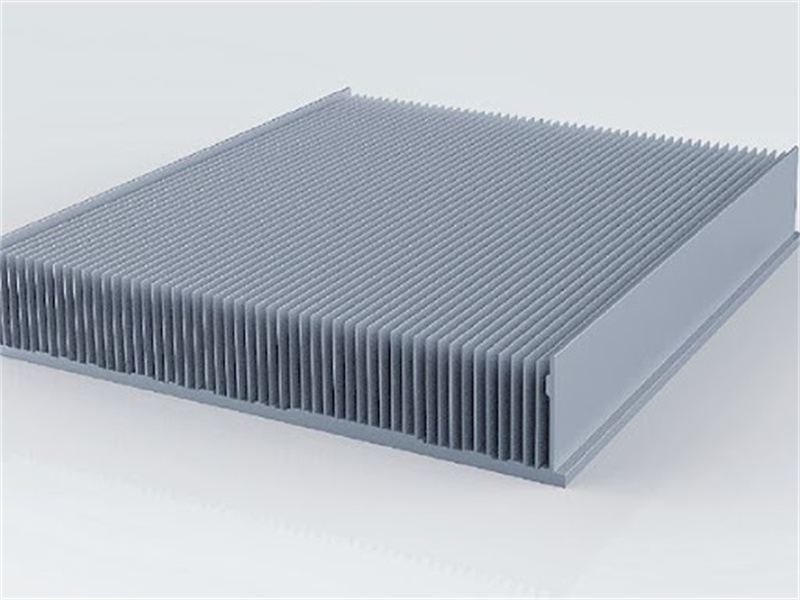

- Heat sinks

- Bottle caps

- Printing plates

- Cookware

- Building materials

- Heat ex-changercomponents

- Food and chemical handlingequipment

- Sheet metal products

- Welding combinations

- Reflectors

- Nameplates

- Deep stamping products

Advantage

- Reflectivity: Aluminum 1100 has a high reflectivity to both visible and thermal radiation and is suitable for applications such as reflective signage, lighting fixtures and solar reflectors.

- Non-toxic and recyclable: Aluminum 1100 is non-toxic and fully recyclable. It can be recycled repeatedly without losing its properties, making it an environmentally friendly option.

- Cost effective: Aluminum 1100 is generally more cost effective than some other aluminum alloys with specific properties, making it the first choice for applications that do not require high strength or specialized characteristics.

- Appearance: Aluminum 1100 has a bright, reflective surface that is properly treated to make it aesthetically pleasing for a variety of decorative and architectural applications.

DC Processing Line Of 1100 aluminum sheet

- Taking the aluminum ingots and little scrap into the melting furnace and melting them into Aluminum liquid.

- Let the Aluminum liquid flow into another furnace to settle the impurity substance,at the same time,add other needed chemical composition to the liquid.

- Pouring the liquid to the mold and then form produce casting slab about 500mm in thickness.

- Scaplingand hot rolling processing line, heating and softening.Then they will enter into the line and rolled into mother coils 6-10mm in thickness.

- Cold rolling line and planishing them to the needed thickness.

- Annealing. This process can change the coils’ physical performance,such as the tensile strength and elongation.The time and times is different in different grades.

- Tension leveler machine.The process is to clean the coil and ensure their good planeness.The final annealing will be operated again if it’s required.

- Cutting the coils into needed length.

- Sending them to storage.

Chemical Component

Al:99.00

Si:0.45

Cu:0.05-0.20

Mg:–

Zn:0.01

Mn:0.035

Ti:–

V:0.05

Fe:0.35

Anodize 1100 Aluminum Sheet

We place the anodized aluminum plate in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and electrolyze it under specific conditions and impressed current. Anodizing 1100 aluminum sheet enhances its process-ability, fire resistance, and dirt resistance. Usually applicable to ceilings, wall panels, furniture, interior decoration, etc.

Packaging Of 1100 aluminum sheet

For the packaging of goods, our factory has been strictly using the international shipping standards for packaging and transportation of goods, use EPE to protect the aluminum sheet,the plastic sheet is to proof water,the carton to prevent from being hit,the steel bar can make it more stable. And we will put a desiccant in every package. In this era of developed transportation, we have widely sold our products to India, Vietnam, Saudi Arabia, Mexico, and other regions.

[wpforms id=”27″]