Brushed aluminum refers to the polishing of aluminum surfaces to create a unique texture and appearance. In the production process, a roller is pressed on the surface of the aluminum sheet to form wire drawing. The result of this technique is a matte, textured finish that can hide scratches and fingerprints.Various applications commonly use brushed aluminum, including architectural decoration, automotive parts, electronic devices, and consumer products, due to its sleek and modern aesthetic.

Technique Parameter About The Brushed Aluminum

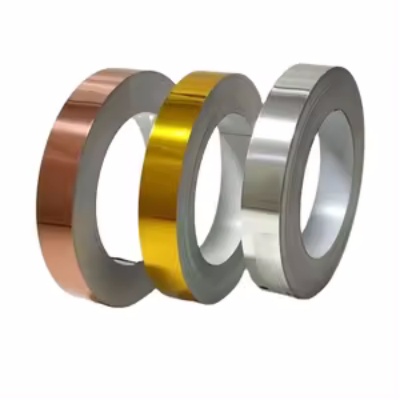

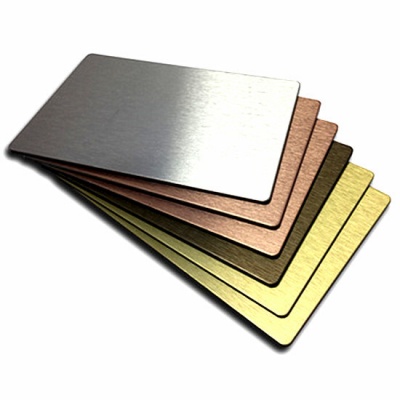

| Common color | Silver, gold, light gold, tea gold |

| Alloy | 1050、1060、1100、3003、3105 or as per customer’s requests |

| Temper | H24 or as per customer’s requests |

| Coating thickness | As per customer’s requests |

| Base aluminum size | 0.45-1.35 mm x 900-1350 mm x C |

| Capacity / month | 500 TONS |

Feature

- Appearance: Brushed aluminum has a distinctively sleek and modern look characterized.This texture adds visual interest and sophistication to products and surfaces.

- Durability: The brushing process creates a protective layer on the aluminum surface, making it more resistant to scratches, abrasion, and corrosion compared to untreated aluminum.

- Fingerprint Resistance: The textured finish of brushed aluminum can help conceal fingerprints and smudges better than smooth surfaces.

- Versatility: Brushed aluminum is versatile and can be used in a wide range of applications across different industries.

- Customization: Brushed aluminum can further customized through processes such as anodizing or powder coating to enhance its appearance.

Advantages of Brushed Aluminum

- The pattern is clear, beautiful and generous, with both fashion and science and technology.

- Excellent weather resistance, no deformation.

- Strong decorative, widely used.

Application of Brushed Aluminum

- Mobile phone cases

- Computer hosts

- Switches

- Aluminum cabinet packaging

- Cabinet panels

- Brushed ACP board

- Fireproof board

- Aluminum picture frame

- Boutique cabinets

- Boutique doors and Windows

- Veneer panels

- Signsboard

- Lighting

- Aluminum strip:6/0.8/1.0 thickness, width 60/80 mm, length 50m/100m, etc.

Drawing technology

- One machine performs both the drawing process and the embossing process.

- The coating precedes embossing for embossing, while embossing precedes coating for drawing.

Drawing difference

- Real brushed thickness requires 0.22 – 1.2mm, with obvious brushed feel and thicker lines.

- Fake brushing has no thickness requirements. It is made with a brushed pattern roller. It is similar to a wood grain and stone grain coated roller. It has no hand feel and fine lines.

Drawing shape classification

- Straight drawing:Refers to the process of machining straight lines on the surface of aluminum plates by mechanical friction

- Cross drawing:Generally in the brushing machine or erasing machine processing. Aluminum or aluminum alloy plate passes through two sets of rollers, and the surface of the aluminum plate is pressed out of the cross grain.

- Random drawing:Under the high-speed running copper wire brush, the aluminum plate moves around and around the friction obtained by an irregular, no obvious lines of matte silk. This kind of processing has higher requirements for the appearance of aluminum or aluminum alloy plates.

- Ripple:Generally in the brushing machine or erasing machine. The surface of the aluminum or aluminum alloy plate is brushed to obtain the wavy pattern by using the axial movement of the roller.

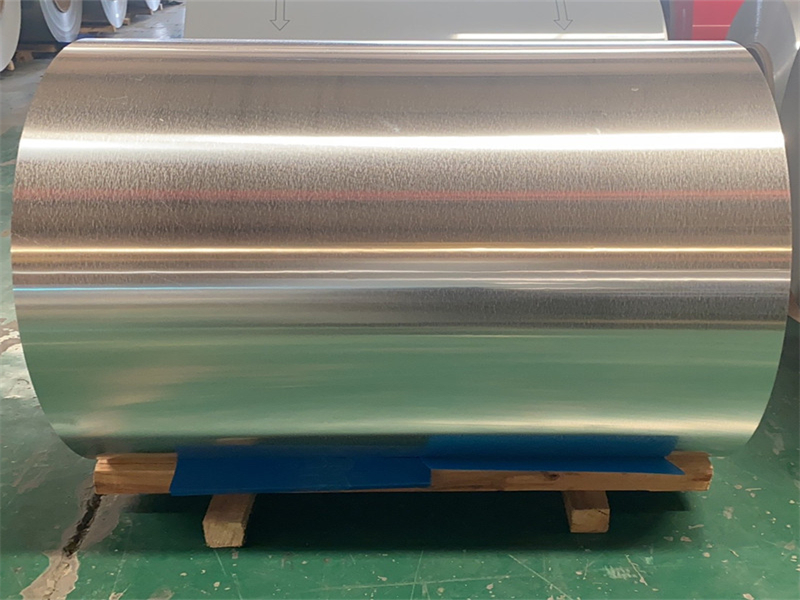

Package

Henan Gusto Trading Company packs and labels its products according to the international wooden package standard or the customer’s requests. We take great care to avoid causing any damage during storage or transportation. Additionally, we tag clear labels on the outside of the packages for easy identification of the product I.D. and quality information.

- International wooden package standard

- Customer’s requirements

If you have interested in our products, please contact us without hesitate!

Welcome inquiry!

[wpforms id=”27″]