Color coated aluminum is an innovative material featuring a protective coating applied to aluminum surfaces. This coating not only enhances the aesthetic appeal of aluminum but also provides additional protection against corrosion, weathering, and UV radiation.

Parameter

| Product name | Color coated aluminum |

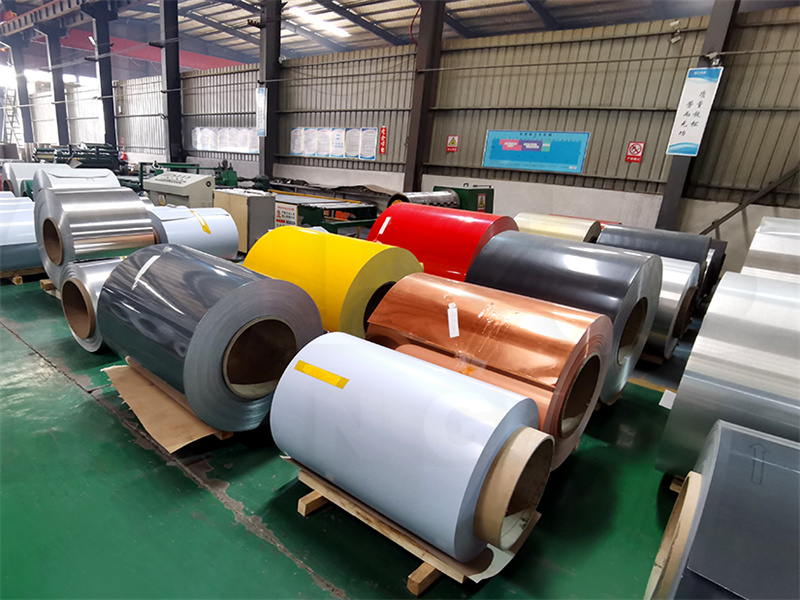

| Color Chart | Black, white, red, brushed gold, mirror silver, imitation wooden, etc. |

| Alloy | 1xxx,3xxx,5xxx series |

| Width(mm) | < 1350 (or as per requirements) |

| Thickness(mm) | 0.25-5mm |

| Length(mm) | 200-1500 (or as per requirements) |

| MOQ | 2-4 tons |

Classifications of Color Coated Aluminum

Solid/Metallic

Under the same premise of using PE/PVDF paint, solid colors and metallic colors are distinguished:

1. White, gray, and black are solid colors and are the cheapest.

2. Metallic silver, flash silver, and silver gray are metallic colors and are the most expensive.

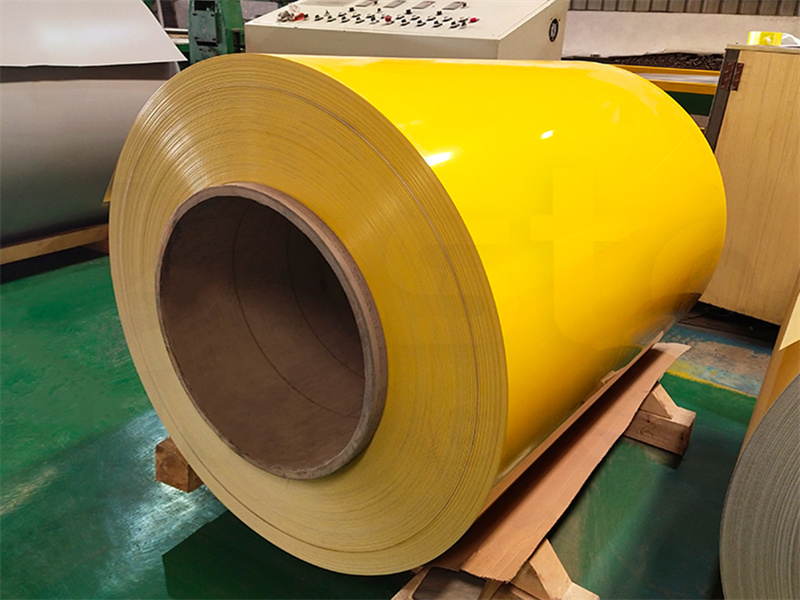

3. Bright red, bright yellow, rose red, and other bright colors, affordable price.

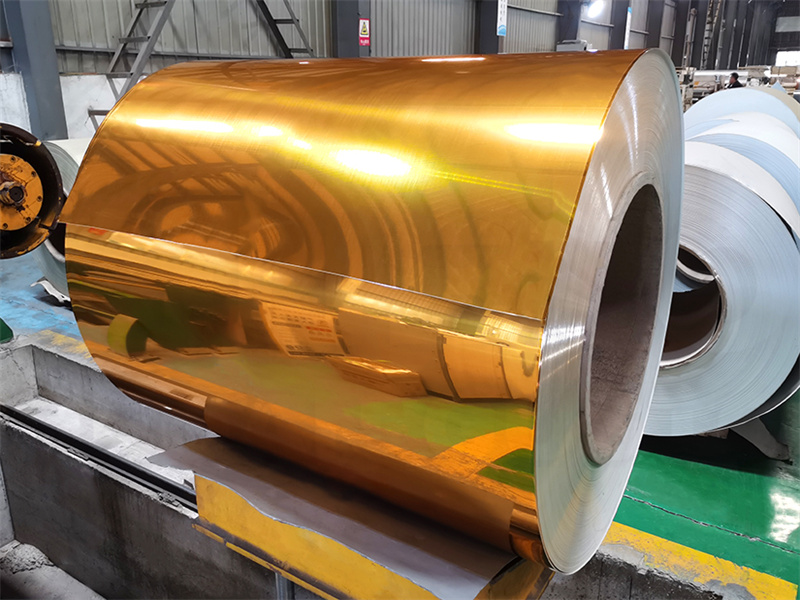

Coated mirror

Common mirror colors: Silver, gold, light gold, tea gold, black.

Commonly used alloys: 1060 H18 H14/H24 3003.

Coating:

1. Silver mirrors generally have no coating and have a reflectivity of 85% – 90%.

2. Gold, light gold, tea gold, and black coatings are 12-14 microns. There is no need to clean the mirror roll after it is rolled back. The coating can be applied directly. Cleaning will affect the surface. The reflectivity is about 80%.

Lamination:

Commonly used membrane colors are blue and yellow, both of medium and low viscosity

Use:

1. Aluminum edge strip: 0.6/0.8/1.0 thickness, width 60/80 mm, length 50m/100m.

2. Interior decoration: silver mirror, 0.3 * 1250 * 2500.

3. Ceiling material: silver mirror, gold mirror, black mirror, 0.6 * 644 * C.

Markets where inquiries have been sent so far: UAE, Brazil, Syria, Iran, Indonesia.

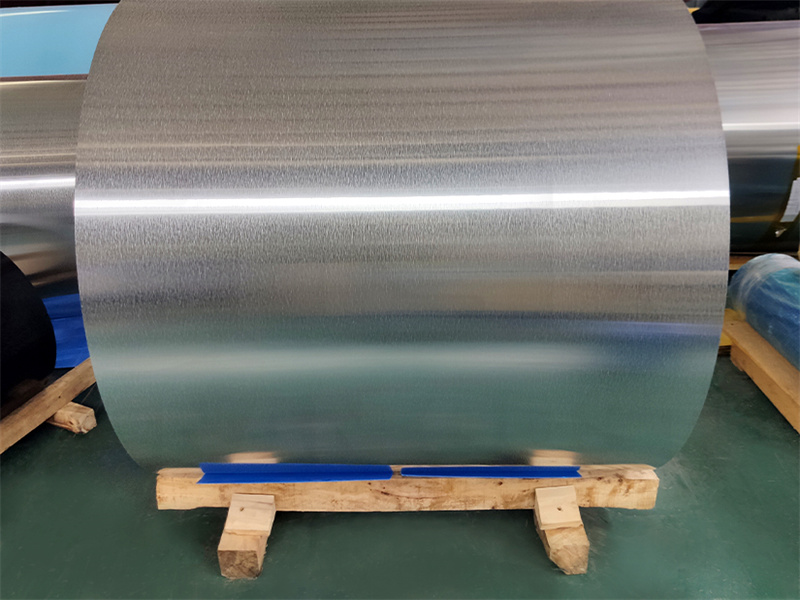

Brushed coated

Common brushed colors: Silver, gold, light gold, tea gold.

Commonly used alloys: 1060 H18 H14/H24 3003.

Brushed:

1. The drawing process and the embossing process are done on one machine.

2. For embossing, coating is done first and then embossing. For drawing, embossing is done first and then coating is done.

Drawing difference

1. Real brushed thickness requires 0.22 – 1.2mm, with obvious brushed feel and thicker lines.

2. Fake brushing has no thickness requirements. It is made with a brushed pattern roller. It has no hand feel and fine lines.

Use:

1. Aluminum edge strip 0.6/0.8/1.0 thickness, width 60/80 mm, length 50m/100m

2. Mobile phone cases, computer hosts, switches and sockets, etc.

3. Aluminum cabinet packaging, cabinet panels, etc.

4. ACP board

Imitation wooden/stone

Stone grained wood grain aluminum plate is a new type of material. Its surface undergoes special treatment to present imitation stone or wood grain textures and patterns. This kind of aluminum plate not only has a unique appearance, but also has the advantages of aluminum material such as lightweight, corrosion resistance and easy processing.

Advantages of Color Coated Aluminum

- Enhanced Aesthetics: Color coated aluminum offers a wide range of colors, finishes, and textures, allowing for endless design possibilities and customization options.

- Weather Resistance: The protective coating on color coated aluminum provides excellent resistance to weathering, UV radiation, and corrosion, ensuring long-lasting performance in outdoor environments.

- Durability: Color coated aluminum is highly durable and resistant to scratching, chipping, and fading, maintaining its appearance and integrity over time with minimal maintenance.

- Versatility: Fabricate color coated aluminum into various shapes, sizes, and profiles. This suits different applications and design requirements, offering versatility and flexibility in use.

- Environmental Friendliness: Color coated aluminum is a sustainable and environmentally friendly material, as it is fully recyclable and requires less energy and resources for production compared to other materials.

Applications of Color Coated Aluminum

- Ceiling: white 1060 H14/H24 0.5 – 0.7 mm, 640*640 mm.

- Gutter: white 3003/3105 H22/H46 0.6 – 0.8 narrow width.

- Roofing: Traffic Red/Traffic Blue 3003 H24 is the most common, some countries may use 1060 instead.

- ACP: common colors, 1060/3003, thickness more than 0.25mm, common width 1220 mm.

- Facades: Monarch Gold, Monument Black, Flash Silver, Poppy Red, and other high-end coatings, hot rolled 3003/3105/5052/5005, thickness 2.85 mm / 3 mm, size 1000 * 2000, 1220 * 2440, 1220 *3050, etc.

- License plate material: Blue front, gray back, about 1.0 mm thick, alloy 1050/1060, 101/121/201 mm wide.

- Car body material: white, 3003/3004H129 only one specification 1.016 x 1244.6 mm x C.

- Roller Shutter: RAL9003, 8014, 7016, 0.45 * 229 * C, anti-scratch material 0.21/0.25 mm * 121/ 125 * C, common color 0.22*172*C.

- UVf printing plate: white 3003 H24/H26, 0.28 * 521 * 725 mm.

- Sublimation sheet/thermal transfer printing: gold, white. thickness: 0.15-0.3mm.

If you need color coated aluminum, please contact us.

[wpforms id=”27″]